01732 496 523

What is ‘Type B’ and Waterproofing Concrete?

The British Standard for Waterproofing, BS 8102:2022, categorises Type B waterproofing as when the concrete structure is integrally waterproof, preventing water from entering.

Most basements are built in concrete, and many waterproofing specifications require at least two types of waterproofing. Therefore, it makes sense to ensure that the concrete box forming the structure also functions as a Type B form of waterproofing.

However, those designing a Type B waterproof concrete structure will often focus on the concrete itself, which rarely leaks, and ignore the parts of the structure where most leaks occur.

Our technical article ‘‘Waterproofing’ of Concrete – Admixtures’, written by Bob Cather, explains that “although the concrete containing the admixture may be shown to have higher resistance to water ingress, this does not mean the structure itself will be more resistant.” The paper further explains what anyone who has ever seen a leaky concrete basement already knows, “that water leakage through a concrete structure is predominantly not through the body of well-compacted concrete, but rather where the concrete isn’t – at cracks, at joints at service penetrations, etc.”

How do you Make Concrete Waterproof?

When designers and contractors correctly proportion and place concrete, it becomes naturally waterproof. This principle has existed since Roman times, when builders reduced the water content and added pozzolanic ash to make dense, non-porous concrete.

As long as the concrete meets BS EN 1992 (Eurocode 2: Design of Concrete Structures), BS 8102:2022 and insurance providers such as the NHBC do not require additional admixtures. However, the NHBC asks structural engineers to ensure that shrinkage cracks remain within 0.2mm.

With the mix design complete, the focus then shifts to the areas most likely to leak — “where the concrete isn’t,” as Bob Cather says.

Examples of where the concrete isn’t are:

- Poor compaction of the concrete resulting in honeycombing or exclusions within the body of the concrete elements

- Construction joints

- Tie-bolt holes

- Service penetrations

If workers fail to compact the concrete properly, honeycombing and cracks can form, making the structure porous and allowing groundwater to leak in.

Construction Joints in Waterproof Concrete

Joints between concrete placements are very common due to limitations on bay size. If installers fail to seal the small gaps between adjacent pours, water can easily enter through the joints. Contractors usually seal these joints with waterstops or waterbars, which expand on contact with water or create a continuous barrier that stops water passing through.

However, several issues can arise with these systems, such as:

- Water is stopped only at the centre of the joint and so passes the first layer of reinforcing steel

- Aggressive water chemicals are not prevented from entering the joints

- Water will pass around the water bar if any porosity exists within or surrounding the joint

The most reliable method of waterproofing joints is to install an injection hose system such as Newton 302 Injection Hose. After 28 days, contractors inject waterproofing resins to permanently seal the full section width of the joint and any porosity around it.

Newton 302 Injection Hose

Newton 302 Injection Hose forms a core part of our Type B system, Newton HydroTank — a reinforced ‘white-tank’ design that prevents water from entering the structure where the concrete isn’t.

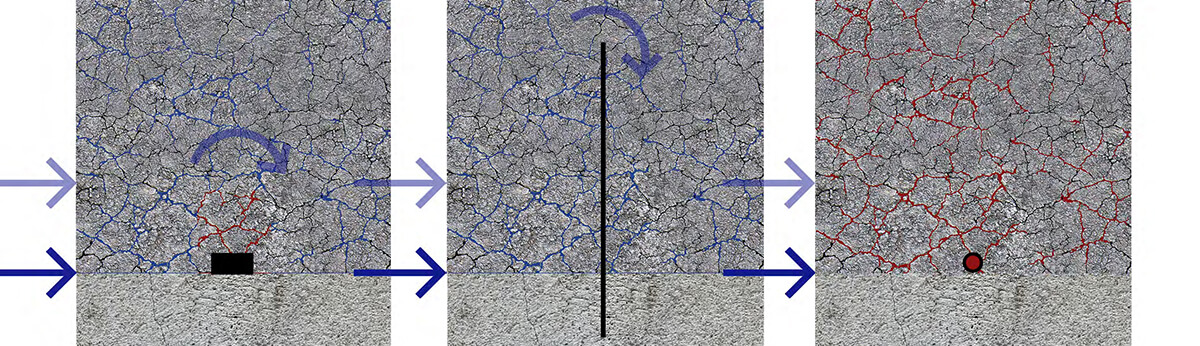

Our RASCOtank System provides another Type B ‘white-tank’ solution for larger projects with multiple bays. Instead of pouring many small bays that create numerous joints, engineers place joint inducers in pre-determined locations and pour one large section, saving significant time.

About three days after placement, the concrete naturally forms joints at each inducer point. After 28 days, engineers inject resins through the inducers to seal the joints and prevent water ingress.

To guarantee a watertight structure that meets BS 8102:2022 and NHBC requirements, Rascor engineers work directly with project engineers to control shrinkage cracks to 0.2mm.

Tie-Bolt Holes

When constructing reinforced concrete structures, formwork must be tied together with bolts to prevent it from bursting during pouring. These tie-bolts pass through plastic sleeves that maintain the correct wall thickness. Once contractors remove the formwork, hundreds of holes may remain — each creating a potential water path.

Many builders try to fill the holes with mortar, but this rarely seals effectively. Because plastic sleeves remain in place, water can travel between the sleeve and the concrete, making this method unreliable.

RiveSTie-Bolt Holes

In contrast, the RiveStop tie-bolt hole sealing system is guaranteed to always reliably seal tie-bolt holes.

The system utilises a patented and sustainable sleeve design that prevents contractors from leaving millions of single-use plastic pipes inside concrete structures. As such, the RiveStop System remains the most sustainable and cost-effective method of sealing tie-bolt holes available today.

The system works by using plastic RivePipe units to space the formwork appropriately. Installers then pass the tie bolts through each RivePipe and tighten them to secure the formwork. After removing the formwork, they extract the RivePipe sleeves with a special tool called a RiveOut, leaving a neat hole through the concrete. The RivePipe sleeves can then be reused on future projects.

Finally, installers mechanically tighten RiveStop plugs with a ratchet tool to fully seal each tie-bolt hole. Overall, the RiveStop method remains the quickest and most efficient way to seal tie-bolt holes, with installation up to ten times faster than traditional methods.

The full process appears in the video below.

Service Penetrations when Waterproofing Concrete

Every building requires service entries, such as cables and pipes, that often pass through basement walls, creating potential weak points. Leaks through these penetrations are common and difficult to fix after the fact.

Newton’s specialist trade partner Hauff-Technik manufactures service entry systems that maintain water, gas, and fire resistance up to 100m of pressure. Their press seals close the gap between the service pipe and sleeve, maintaining full waterproofing integrity.

The video below shows the installation of the Hauff-Technik press seals. These seals waterproof the space between the service itself and the service sleeve.

Overall

Our Type B systems follow a simple 4-step approach to create watertight concrete basements:

- Well-placed concrete designed to BS EN 1992

- Sealing the full section width of the construction joints with injection hoses and resins

- Sealing the tie-bolt holes with the unique RiveStop System

- Sealing services with Hauff-Technik service entry systems

For technical advice or system design support, contact our team on 01732 360 095 or email tech@newtonwaterproofing.co.uk.

FAQ

How do you permanently waterproof concrete?

There are several methods to permanently waterproof concrete, including the use of concrete sealers, membranes, and coatings. Contractors apply concrete sealers as liquid coatings to the surface of the concrete, creating a water-resistant barrier. They lay membranes — sheets of waterproof material — over the surface before pouring the concrete. After forming the concrete, they apply coatings to the surface, which are thicker than sealers.

Is a concrete Waterproofer the same as a sealer?

While both protect the surface, a sealer acts as a protective layer. On the other hand, a waterproofer penetrates deeper to fill cracks and pores. This provides long-term resistance to moisture.

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.