01732 496 523

Summary

-

Installation of Newton System 500 internally to the basement.

-

Two Newton Titan pumping systems were used in this project to manage waste water.

-

This stunning property is now free from damp problems.

Newton System 500 fulfils all Listed Building requirements in this Georgian Manor House. Newton Pumping Systems installed to manage waste water, including two Newton Titan pumps and battery backup systems.

The Project

This Georgian property is situated in one of most sought after locations of Royal Tunbridge Wells in Kent. The client converted this extensive 15 room basement into a luxury stand alone property; converting the space from a damp storage area into a Grade III habitable apartment.

The main contractors, Brambilla Ltd, were awarded the contract and subsequently engaged Newton Specialist Basement Contractor, Advanced Preservation, to design and install the Newton System 500 cavity drain system.

The Solution

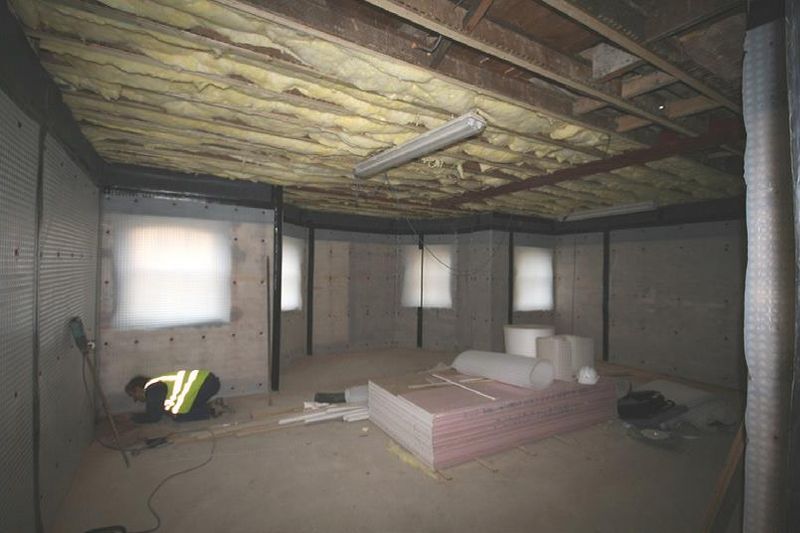

The team installed Newton System 500 across all external and internal areas of the property. They curtain-hung the Newton 508 membrane to the walls using Newton Multiplug, and installed Newton 503 in the confined basement areas.

After the team installed and levelled the new concrete slab, they placed Newton Basedrain on top of the slab around the retaining walls. They installed 50 mm of closed-cell insulation abutting the drainage channel, then laid the Newton 508 membrane over the insulation and sealed it to the Basedrain upstand. Because head height concerned the client, the team introduced a specialised pumped polymer-based screed. This product was pumped on top of the under floor heating system which was installed over the floor membrane. The client was then able to introduce a 40mm screed instead of the standard 65mm sand and cement screed finish.

Two Newton Titan pumping systems are in use alongside the Basedrain with battery back-up support.

The Result

The project required minimal surface preparation, and the client now has a clean, effective solution. The solution allows the contractor to meet Listed Buildings requirements as well as sound and insulation regulations.

Benefits:

This stunning property has a serviceable and effective water management solution. The team installed extendible access ports into the perimeter channel, allowing the installer to service the system at a later date. The engineered screed saved 25 mm of overhead height and allowed construction to continue 24 hours after pouring.

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.