01732 360 095

‘Tanking’ is a long-established name for external or internal waterproof barriers that are designed to protect below ground structures against water from the ground, such as cellar tanking.

Referred to as ‘Type A Systems’ in British Standard 8102:20022 the ‘Code of Practice for the Protection of Below Ground Structures from Water Ingress’, external tanking can be anything from a sheet or liquid membrane to a cement render or slurry. The type of product used depends on the form of construction and sequence of the build, and typically forms part of a larger waterproofing system.

Type A waterproofing systems can be applied either;

- externally (on the positive side) such as the Newton HydroBond System

- or internally (on the negative side) such as the Newton HydroCoat System

Traditionally, these waterproof tanking systems were made using bitumen or asphalt-based liquid. As a result, external tanking is still referred to as a ‘black tank’ across Europe, and whilst the original liquid products were replaced with pre-manufactured, polymer-modified bitumen sheet products, these types of product can also present issues of their own.

To combat this, in the UK there has been a great deal of evolution and development over the years to overcome the problems associated with partially bonded bitumen sheets. The result is a selection of advanced tanking products that offer a safer solution and form a tighter, more homogenous tanking system.

How do you Tank an External Wall?

When deciding on the correct external tanking system, it is important to take into account the recommendations outlined in both BS 8102:2022 and the technical standards documents of your insurance company, where typical defects that may occur in waterproofing systems are explained. These usually include:

- defects owing to design;

- defects owing to poor workmanship;

- inappropriate use of the materials being used and defects owing to the specific properties of the materials being used; and

- defects caused by follow-on trades and site operations.

However, if your aim is to prevent water from penetrating a below-ground structure, then only a fully bonded tanking system should be used.

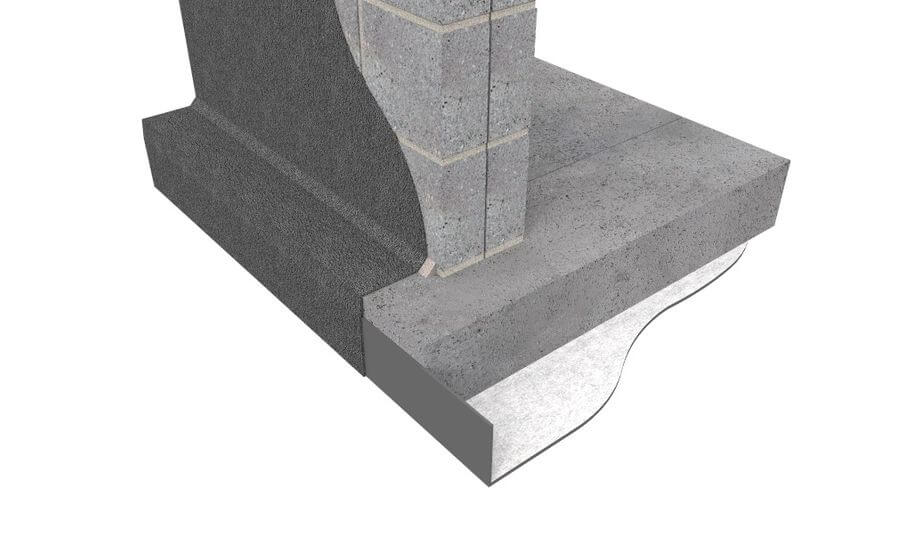

When the structure is being newly built, the most effective external tanking system is a fully bonded sheet such as HydroBond 403 Plus that is pre-applied under the concrete slab. Newton HydroBond 403 Plus is particularly effective as it contains a hydrophilic polymer that self-seals around any small defects or fixings.

The HydroBond 403 Plus external tanking membrane is also available in two variants, the second of which, HydroBond 403 Plus-GB, also provides protection against ground gases, as explained in the following article:

Creating a Barrier Against Both Gas and Water

Where pre-application is not possible, a post-applied external tanking system is required instead. In this case, a seamless and fully bonded liquid applied membrane such as HydroBond 109-LM can be applied to basement and foundation walls. With the benefit of not requiring adhered laps, this is one major potential defect point that has been designed out by using liquid-applied membranes. The membrane is also fully bonded to eliminate lateral migration of water even if there was a defect.

When both pre- and post-applied external tanking systems are required, HydroBond 109-LM can link up with HydroBond 403 Plus to ensure a continuous waterproof barrier. The post-applied tanking can also be extended over a buried deck or soffit if the structure requires it.

Customer Success Stories

Our latest customer reviews from Feefo - the award winning review platform

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.