- Dual Functionality: HydroBond 403 GB not only provides exceptional waterproofing but also acts as a gas barrier, protecting against radon, carbon dioxide, and hydrocarbon gases in compliance with BS 8485:2015+A1:2019.

- Self-Healing Membrane: The self-healing technology ensures automatic sealing of small punctures, maintaining waterproof integrity even during construction activities.

- Complete Structural Protection: As part of the comprehensive HydroBond® System, HydroBond 403 GB integrates with post-applied membranes and drainage boards, offering a full waterproof envelope suitable for various below-ground and earth-retained structures.

- Long-Term Durability: Supported by certifications and accepted by NHBC, HydroBond 403 GB provides a robust waterproof and gas barrier for the life of the building, with an expected lifespan of at least 60 years.

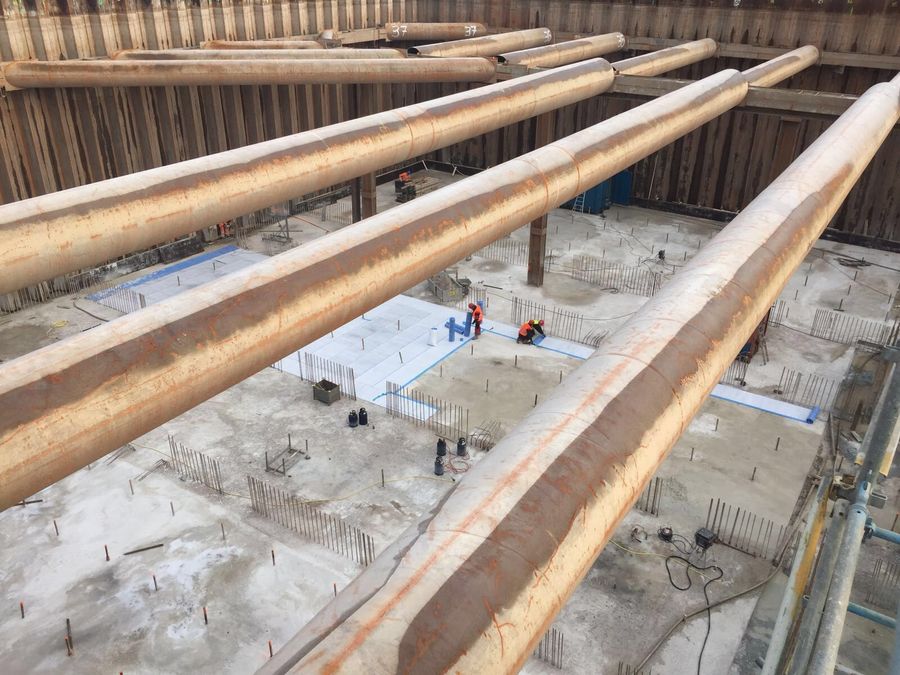

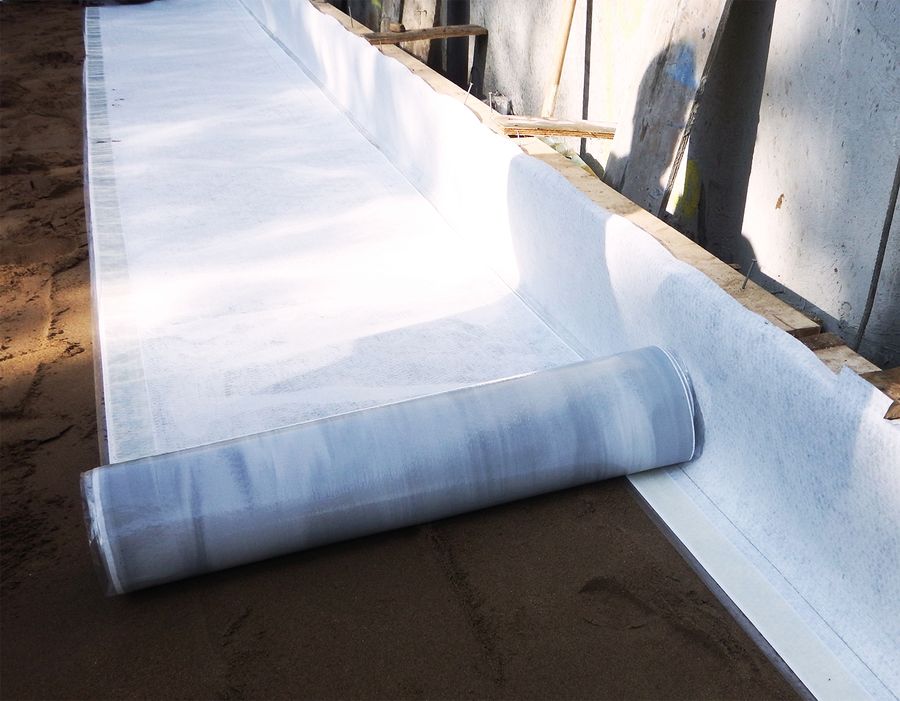

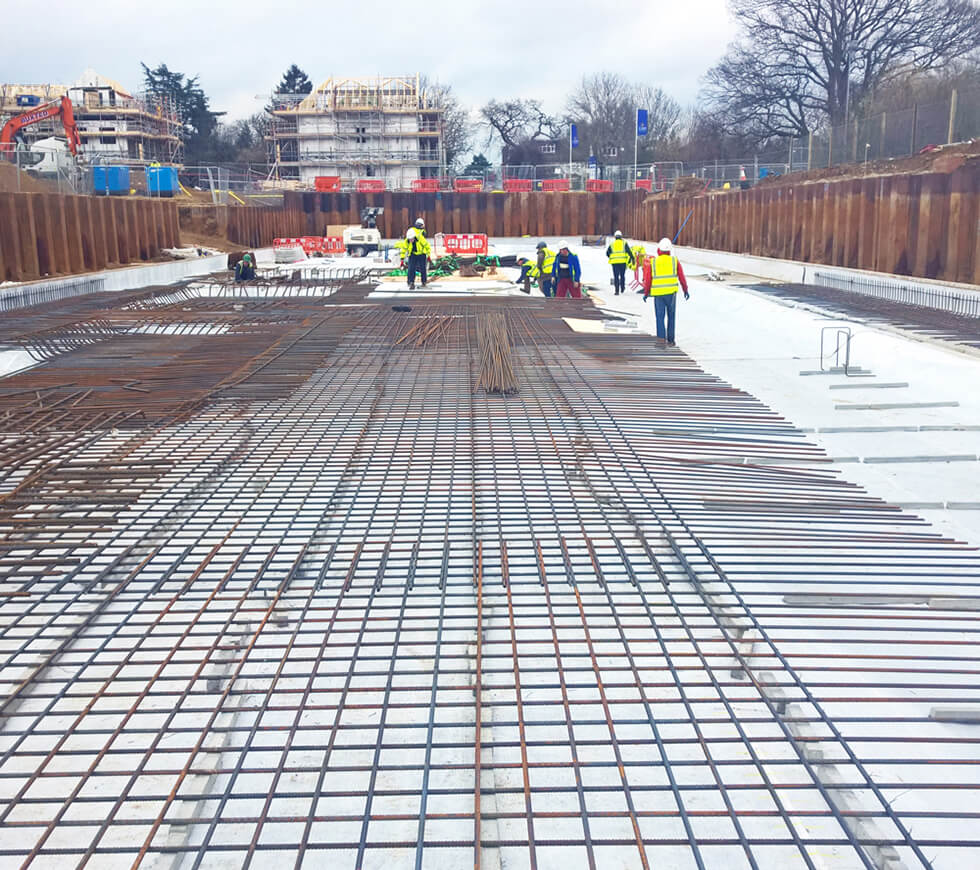

Newton HydroBond 403 GB is a high-performance, self-healing, composite sheet membrane with exceptional waterproofing capabilities, that also provides ground gas resistance (in compliance with BS 8485:2015+A1:2019) to radon, carbon dioxide and hydrocarbon gases. When fitted above the raft support or to building line formwork, the membrane locking fleece is encapsulated into the newly placed concrete, becoming fully-engaged to prevent water tracking.

If the waterproof LDPE layer is punctured, the exposed hydrophilic coating expands, preventing water ingress and effectively sealing small holes that may be accidentally formed during fixing of the reinforcing steel or the placing and compaction of the concrete.

Newton HydroBond 403 GB is a component of the HydroBond® System that also includes post-applied waterproofing membranes, protection and drainage boards, providing a complete waterproof envelope to the structure to achieve Type A (barrier) waterproofing suitable for Grades 1, 2 and 3 as defined by BS 8102:2022. The HydroBond System is suitable for all below-ground and earth-retained structures from domestic basements to the largest civil engineering projects.

Correctly protected, the Newton HydroBond System will provide, under normal service conditions, a durable waterproof barrier for the life of the building to which it is installed; the expected lifetime of the building itself should be at least 60 years.