01732 360 095

Newton HydroBond System

External Type A Waterproofing

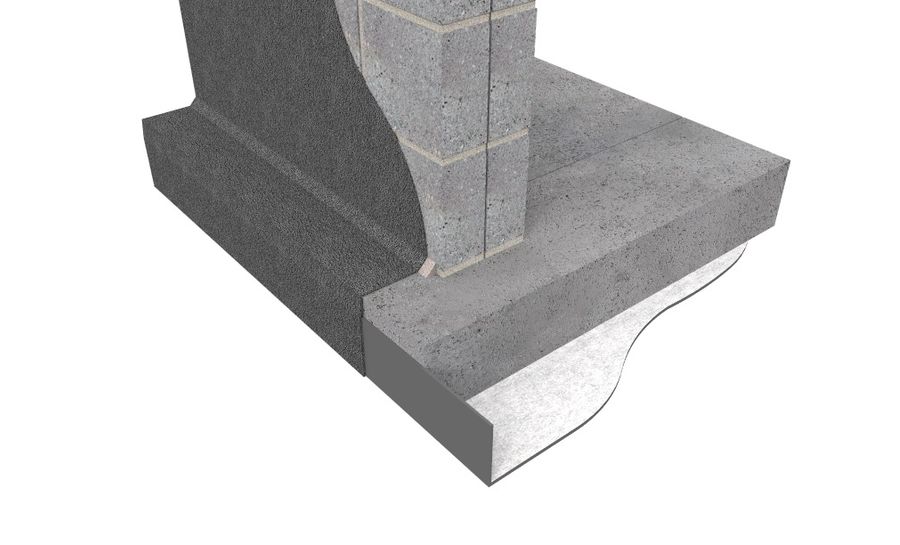

The Newton HydroBond System is a high-performance, Type A waterproofing system designed to be applied to the outside of the structure.

This system can be either pre-applied below the concrete raft/slab and wall building line, or post-applied where conventional formwork is removed to expose the outside of the basement walls.

Depending on the type of structure it is applied to, once installed, the combination of selected products within the HydroBond System can provide a continuous barrier around the full extent of the structure.

The HydroBond System can provide protection against both groundwater and ground gasses such as radon, methane, and carbon dioxide, depending on the products employed, making it the ideal solution where protection from any or all of these elements is required.

Type A Waterproofing

The British Standard for Waterproofing 8102:2022 is the ‘Code of Practice for Protection of Below Ground Structures Against Water Ingress’ and defines Type A waterproofing as “barrier protection” which is applied to either the internal or external surface of a structure in order to resist the pressure of water trying to enter the building.

Type A membranes are the products that are referred to when people talk about the process of “tanking” a basement in order to protect it from water ingress.

Barrier waterproofing membranes that can be applied to the external ‘positive’ side of the structure include both pre-applied, self-healing sheet membranes, and post-applied liquid membranes that can be linked to the above-ground DPC in order to completely encapsulate, or “tank”, the basement in a continuous waterproof layer.

Pre-Applied Membranes

- Self-healing membrane

- Very flexible

- Resistant to radon, carbon dioxide and hydrocarbons

- BDA approved

- High-performance membrane

- Pliable and durable

- Radon protection membrane

- Forms a full mechanical bond

Post-Applied Membranes

- Self-adhesive membrane

- Flexible and durable

- Resistant to aggressive ground water chemicals

- Resistant to impact

- Self-adhesive membrane

- Flexible and durable

- Resistant to methane and carbon dioxide

- Resistant to aggressive ground water chemicals

-

- Bitumen/ rubber liquid membrane

- Radon gas certified

- Extremely puncture resistant

- Flexible

- Cold-applied liquid rubber membrane

- Radon gas certified

- Extremely puncture resistant

- Flexible

Ancillary Products

Adhesive jointing tape for the three pre-applied membranes

HydroBond Protection Board

Protection board that is applied to the waterproofing to protect the walls during the back-filling process

Combination Waterproofing

Where the assessed risks are deemed to be high or where the consequences of failure to achieve the required internal environment are deemed too high, BS 8102:2022 recommends combining two or more Types of waterproofing. The Newton HydroBond System can therefore be combined with various other Newton systems, including our ‘Type C’ Newton CDM System.

The Newton Technical Team will always ensure the end user’s desired internal environment is achieved with the right combination of structural waterproofing methods in accordance with current legislation and best practice. Professional waterproofing designers should always consider using more than one type of waterproofing to provide enhanced protection to the structure and achieve the necessary environmental grade.

Gas Protection

If protection from ground gases is also a requirement, then Newton will always recommend waterproofing products that also have third-party tested gas resistance. Section 4 of the British Standard for Waterproofing, BS 8102:2022 states that “Strategies for dealing with all external sources of groundwater, surface/flood water, soil gases and contaminants should be determined from the very earliest stages of the planning and design processes for any project involving below ground structures”.

Several of the products in our HydroBond System meet the standards required to protect against both water and below-ground gases. However, suitable products must always be paired with sensible design, and best practice dictates that the most effective combined waterproofing and gas proofing designs always combine multiple forms of protection, and always include ‘Type C’ cavity drain protection, in the form of the Newton CDM System.

For more information on the Newton HydroBond System and to find the products best suited to your project requirements, call our Technical Team on 01732 360 095 or email tech@newtonwaterproofing.co.uk.

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.