01732 360 095

Newton Waterproofing supply a variety of methods for sealing penetrations through below ground structures. As is usually the case with systems that resist ground water pressure, good forward planning and the use of products that have the required design performance is paramount.

Water has the potential to pass between pipes and cables within the sleeve but also between the sleeve and the concrete, and so the selection and method of waterproofing the sleeve is just as important as the method of waterproofing between the services within the sleeve.

Waterproofing Service Entry Sleeves

Cast-in-situ

If the number and location of the service sleeves is known, the sleeves can be positioned ready for the placement of the concrete.

The Hauff ZVR is a cement coated wall sleeve that reacts with the wet concrete to form a homogenous bond that is fully waterproof and gas proof. The sleeves are available in diameters from 50mm to 300mm and suitable for wall thickness from 180mm to 900mm. Each diameter is exact to tight tolerances ensuring that mechanical sealing systems details below are always correctly sized for optimum performance.

Core Drilled

Where service entry positions could not be determined before the concrete placement, the sleeve will need to be core-drilled.

Correct Sizing

With both cast-in-situ and core drilled sleeves, the optimum size of the sleeve is determined by the size and number of services passing through each sleeve. Each of the sealing methods detailed below have size and tolerance requirements. The Newton Technical Team can assist on the correct sizing for each method.

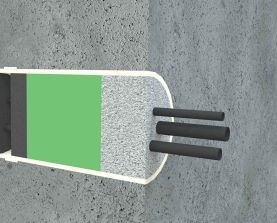

Modular Cable Entry System

Where multiple entries pass into the building in close proximity, the Hauff HSI system may be preferred, which are available in 150mm and 200mm internal diameters.

Service Entry Sealing Systems

Pre-planned

Where a Hauff Sleeve as detailed above has been installed, it is likely that the type of service and

number of services passing though the sleeve is known and all that is required to complete the project is the correct selection of the Hauff Press Seal.

Mechanical Press Seals are by far the safest method of sealing service entry penetrations, and with a little planning, are guaranteed to always provide a long lasting, waterproof solution.

Press Seals are available in steel or polymer and in a variety of configurations, but in most cases the Standard Press Seals will be suitable. Split Seals all for installation is possible even when the pipes or cables are already passing through the sleeve.

The conduit used to protect the cables within the ground should not pass through the service entry sleeve as an effective seal to corrugated or ribbed conduit cannot be guaranteed.

Unplanned or Failed Services

Where the service sleeve is already in place, or where the service entry is leaking and requires remediation, the Hauff Press Seals as detailed above will in most cases be the easiest and safest method of sealing the service entry.

There will be scenarios though where the Hauff Press Seal cannot be used such as:

- Non-cylindrical sleeves such as letterbox openings or where a plastic pipe used as a sleeve has deformed

- Where ribbed or corrugated conduit passes through the sleeve and cannot be removed

- The internal diameter is not suitable

Where a mechanical press seal cannot be used a mastic or resin sealing systems are often the only options available. Newton are distributors of two leading mastic sealing systems, Stopaq and Filoseal, and the LeakPlug foaming resin system.

Stopaq

The main USP of Stopaq is that it is very effective at sealing leaking services.

There may be scenarios where Stopaq is used in conjunction with the other sealing systems due to its ability to control even heavy volumes of water ingress.

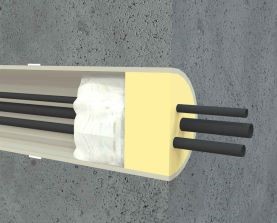

FiloSeal

Filoseal cannot be used where water is passing through the services but the FiloSeal +HD Fire variant has the advantage of being rated to up to 4 hours fire resistance.

It is also better suited to filling larger spaces between the sleeve and services due to the support provided by the hexagonal tubes.

LeakPlug

The LeakPlug Kit comprises of 0.5 kg of a PU foaming resin, 0.05 litres of catalyst and 40 g of polyester

fibres. These all are mixed within a plastic bag to form a wad of material. Immersion in water activates the foaming action of the resin and the wad is pushed hard between the services to seal the leaks.

| Leak sealing of running water | Hot pipes | Fire rated | Pressure rating | Guarantee | Gas performance | Time to install | |

| Hauff | Yes | Yes | Yes* | 25-100m | 100 years | Fully gas tight | 5 mins per service |

| Stopaq | Yes | No | No | 10m | None | Limited | 15 mins per service |

| Filoseal | No | No | Yes** | 10m/20m | None | Limited | 15 mins per service |

| LeakPlug | Yes | No | No | No data | None | None | 10 mins per service |

*With Fire Protection Kit S90, giving fire resistance class S90 in accordance with DIN 4102-9

** FiloSeal+HD FIRE, giving up to 4 hours fire resistance to BS EN1366-3 2009

Specification

Newton can assist with the specification of all of the systems mentioned above. We just need to know the sizes and number of the pipes of cables passing through the sleeve, or the sleeve size and shape if this is known.

| Number | Service | O/D of service – mm | Sleeve I/D mm | |

| Example | 2 | Water and electric | 34 and 50 | 100 |

| Example | 4 | Pipe | 63 | 100 |

Newton will then by return confirm the full specification including the purchase product codes, prices, and availability.

Combining Systems

If the service sleeve is out of tolerance for Hauff Press Seals and a mastic system is to be used, Stopaq and Filoseal can be combined to provide the required performance. For example, if fire protection is required but the service is leaking, the leak can be stemmed first with Stopaq prior to the installation of the FiloSeal+HD FIRE.

Sealing of Waste Pipes

If the use of the Hauff ZVR cement coated wall sleeve is not possible and alternatives such as drainage pipe have been used, or where drainage pipes must pass through the slab, alternative sealing methods are available:

- Hauff KG-FIX – Forms a watertight seal between 110mm O/D drainage pipe and the concrete

- Newton HydroTank 315 Waterbar – Hydrophilic (swelling), polymer waterbar, primarily used for the sealing of construction joints, but can also be used for the for the sealing of elements that pass through the structure

- Tundish Waste Pipe Entry – Provides an optimum water and gas-tight seal through concrete floor slabs to the underground sewer pipe

- Universal Wall Entry – Optimized flow through wall penetration – prevents deposits and back water in the sewer system. Three 3-ribbed seals for sealing in double walls/element walls

Associated Products

Tie-Bolt Hole Sealing System – Rivestop

- RivePipe – A removable, reusable and recyclable formwork tube that protects tie bars within the concrete, and once removed leaves a clean, uniform tie hole.

- RiveOut – The manual extraction tool for easily removing RivePipe tubes from concrete walls in a matter of seconds.

- RiveStop – A patented rivet system that is quickly and easily installed, expanding to 50% of its original diameter to hermetically seal any tie-bolt holes left by the RivePipe.

Overall, RiveStop delivers savings of up to 90% in terms of both man hours and material costs compared other alternatives in the UK waterproofing market – check out the RiveStop System.

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.