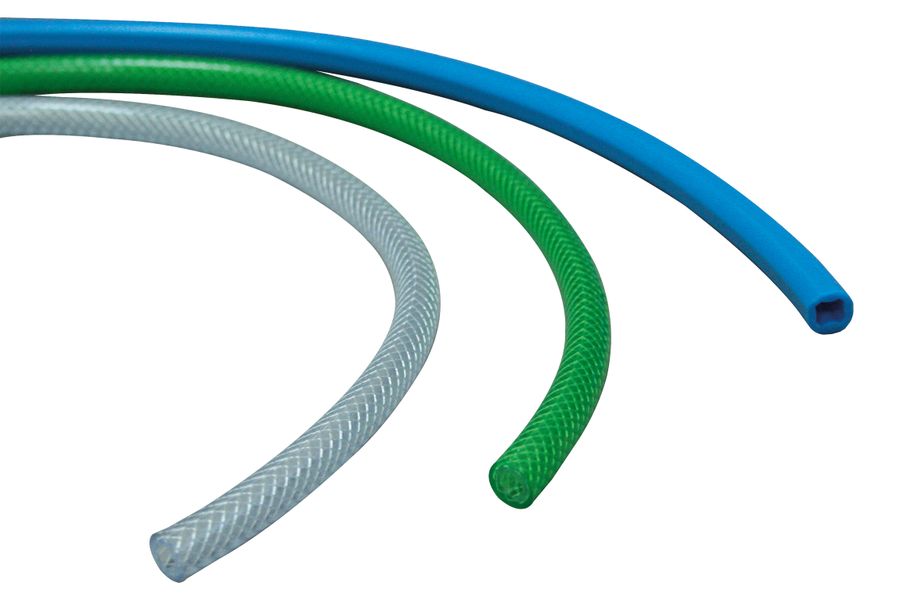

A high performance waterbar system installed within and used for sealing construction joints in earth-retaining and water-retaining concrete structures. When injected with injection resin, the material penetrates into the concrete surrounding the construction joint to permanently seal any cracks, capillaries, pores and honeycombing within the structure.

HydroTank 302 Injection Hose features micro-ports equally spaced over the entire circumference of the hose, and when injected with injection resin at 1-bar of pressure or above the microscopic ports open and the low-viscosity resin penetrates deeply into the concrete surrounding the construction joint.

The injection hose is compatible with both polyurethane and acrylic injection resins, and when installed and injected correctly HydroTank 302 Injection Hose improves the water tightness of the ‘Type B’ waterproof structure by sealing the joints and encouraging improvements in the quality of the concrete placement.