- Effective Water Sealing: High-grade hydrophilic waterbar with exceptional elasticity and tensile strength, swelling up to 9 times its original size upon contact with moisture, providing reliable sealing against water leaks in both cast-in-place and precast construction joints.

- Versatile Application: Ideal for sealing structures in aggressive water environments such as sewage treatment plants, biogas plants, and liquid waste holding tanks, thanks to its high resistance to acids, alkalis, and organic solutions.

- Comprehensive Joint Sealing: Ensures full and reliable joint sealing, particularly suited for non-compressed joints like those at the junction between slabs and walls, offering durable protection against water infiltration in critical construction areas.

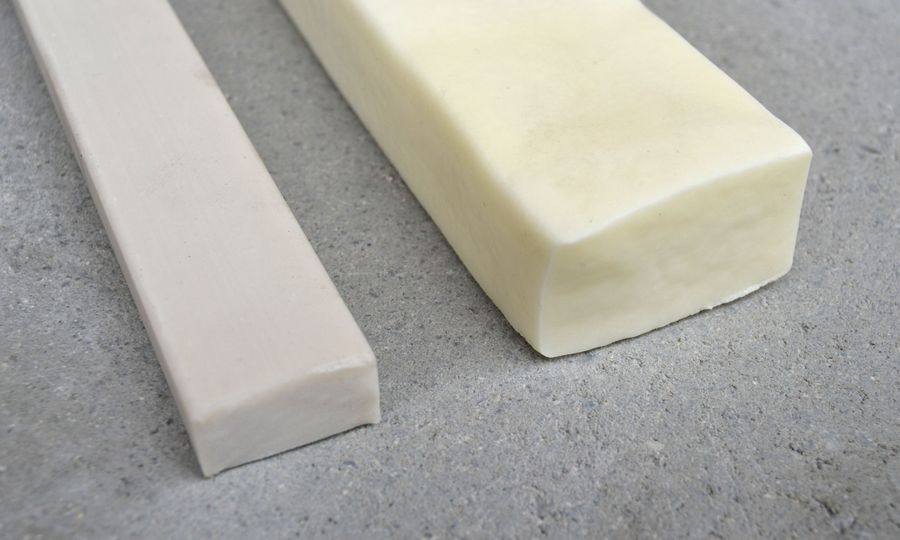

A high grade, hydrophilic waterbar with high elasticity and high tensile strength, made from a polymer which swells when in contact with moisture. Ideal for sealing structures against water leaks to both cast-in-place concrete and precast construction joints.

The swelling is achieved through hydrophilic acrylate polymers, which are inseparably embedded within the butylene carrier material. This results in high elasticity and exceptional tensile strength, even when fully expanded within the joint.

Due to its high resistance to acids, alkalis and organic solutions, HydroTank 315 Waterbar can be used to seal joints where aggressive water is expected such as within sewage treatment plants, biogas plants and liquid waste holding tanks.

HydroTank 315 Waterbar swells up to 9 times its original size when in contact with water, sealing the joint fully and reliably. The product is particularly suited to sealing non-compressed joints such as at the junction between slab and wall.