01732 360 095

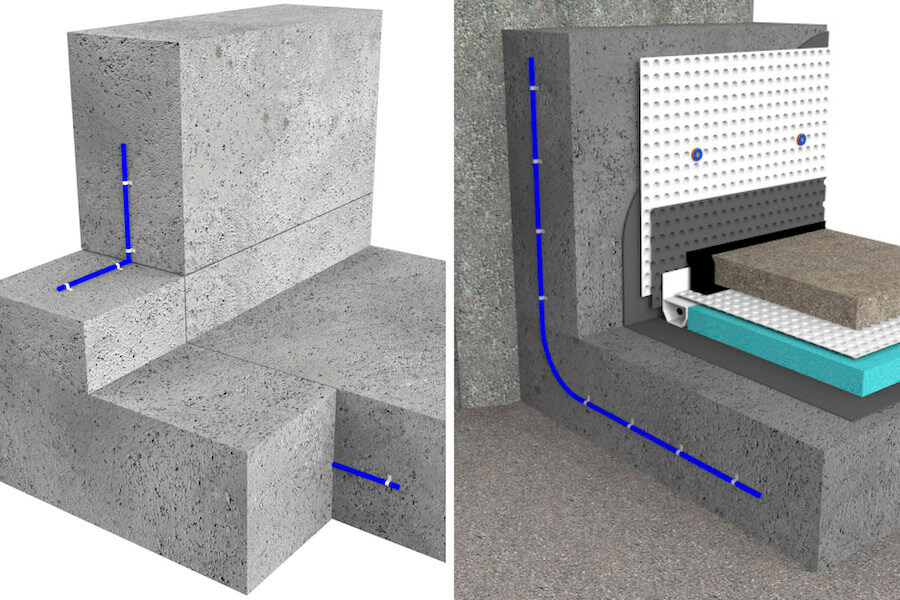

Newton LeakInject System

The Newton LeakInject System is designed to seal and repair cracks and holes in walls, floors, joints, foundations and concrete construction that suffer from water infiltration. Cracks and holes in structures are typically caused by stresses imposed from the ground surrounding them, as a result of loading, expansion, ground movement or shrinkage.

When left untreated, this damage can affect the stability, safety and durability of a structure. When sealing cracks, Newton recommends the LeakInject System as an effective technique for a variety of structures including:

- Basements

- Tunnels

- Bridges

- Underground car parks

- Water treatment facilities

This system consists of products manufactured by leading Belgium-based injection resin specialists TRADECC after a partnership was formed between Newton and TRADECC in 2019.

We can supply TRADECC’s full range of high-performance injection resins, as well as the required ancillary products, installation products and machinery.

Injection Resin Products

-

- Two-component

- Fast foaming

- PU resin

- Dense, flexible foam

- Single-component

- Low viscosity

- PU resin

- Flexible foam

- Single-component

- Low viscosity

- PU resin

- Semi-rigid foam

- Two-component

- Fast reacting

- PU resin

- Low viscosity

-

- Five-component

- Highly elastic

- Acrylic resin

- Low viscosity

-

- Four-component

- Highly elastic

- Acrylic resin

- Low viscosity

LeakInject Ancillaries

-

- Two-part packers

- Two sizes as standard

- Specialist sizes available

- Easy-to-use

- Drill-powered

- Supplied with drill adaptor

- Pumping resins in injection hoses

- Single-component

- Cement-based

- Structural mortar

- Fast-setting

-

- Fast-setting

- Polymer compound

- Stops running water

- Exceptional durability

Combination Waterproofing

British Standard 8102:2022 recommends combining two or more Types of waterproofing for more robust waterproofing protection. Therefore, the Newton LeakInject System can be combined with various other Newton systems, including the CDM System, HydroBond System and HydroSeal System for Type C and external and internal Type A waterproofing respectively.

The Newton Technical Team will always ensure the end user’s desired internal environment is achieved with the right combination of structural waterproofing methods in accordance with current legislation and best practice. Professional waterproofing designers should always consider using more than one type of waterproofing to provide enhanced protection to the structure and achieve the necessary environmental grade.

For more information on the Newton LeakInject System and to find the product best suited to your project requirements, please fill in the form below, or call our Technical Team on 01732 360 095 or email tech@newtonwaterproofing.co.uk.

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.