01732 496 523

Summary

-

ASF have specialist operatives trained in injection resins

-

The numerous access shafts also ensure the power tunnels are easily accessible for future work and maintenance

-

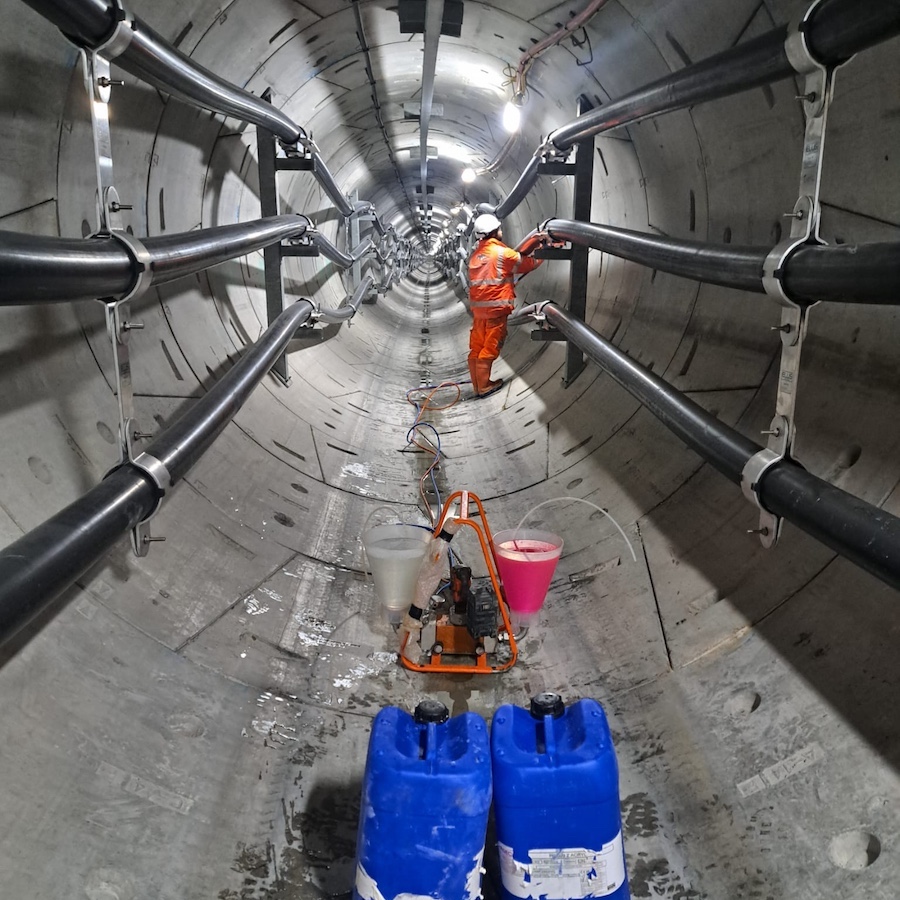

The finished power tunnel provides a clean, accessible route for the high voltage electrical cables

-

Final checks and injections after the tunnel was completed

The London Power Tunnels

Starting in spring 2020, the London Power Tunnels is an immense seven-year and £1 billion project by the National Grid to rewire South London via deep underground tunnels. Resin injection tunnel waterproofing methods will be used throughout the project.

Most of South London’s electricity providers transmit power through underground cables, traditionally located just below the road surface. However, crews carry out maintenance work at street level, which can be disruptive.

By housing new, high-voltage cables in deep underground tunnels, the benefits include:

- Less disruption during construction as the majority of works will take place deep underground

- Crews can carry out future repairs and maintenance without disrupting traffic, residents, or businesses.

- Engineers can install additional cables in the tunnels to meet future demand.

The new tunnels will upgrade the network’s capability to ensure it is ready for London’s future energy needs. Resin injection tunnel waterproofing helps to fulfil the requirements on site.

The Project

Engineers at AECOM designed the 32.5 km tunnel system. The tunnels have a 3 m diameter, running deep below roads, rivers, canals, and tube lines. Stretching between Wimbledon and Crayford, the tunnels lie between 10 m and 63 m below street level. The project required multiple vertical access shafts, the workers built these shafts along the route.

The shafts ranged from 9 m to 15 m in diameter, some reached depths of up to 55 m. These shafts let the ASF Waterproofing team access the tunnels safely, using them to carry out resin injection waterproofing.

A tunnel boring machine (TBM) constructs the tunnels and places precast, interlocking concrete segments against the tunnel walls. Workers fit the segments with rubber gaskets to seal the joints; however, these gaskets sometimes become dislodged, damaged, or improperly seated, allowing groundwater under considerable hydrostatic pressure to seep through.

ASF Waterproofing Specialists were appointed by the Hochtief Murphy Joint Venture to undertake resin injection of these joints to seal them against water ingress.

The Solution

As experts in below-ground injection resin waterproofing, ASF Waterproofing were able to bring their considerable experience to bear on this project too. Utilising a variety of products, such as our exclusive range of advanced acrylic injection resins from TRADECC, ASF were able to waterproof the joints, providing a Type B solution in line with Section 11 of British Standard 8102:2022 for waterproofing.

The Result

ASF Waterproofing worked on Phase 2 of the London Power Tunnels project for three years and fully sealed all joints in the tunnel and access shafts against water.

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.