01732 496 523

When constructing or renovating below-ground spaces, understanding the distinction between damp proof membranes (DPMs) and waterproofing membranes is crucial. While both act as a barrier to moisture, they are designed for different applications and perform very different tasks.

This blog explores the differences between the two types of products, the limitations of DPMs, and why advanced waterproofing solutions like cavity drain membranes and cementitious coatings are required for basement waterproofing.

What is a Damp Proof Membrane (DPM)?

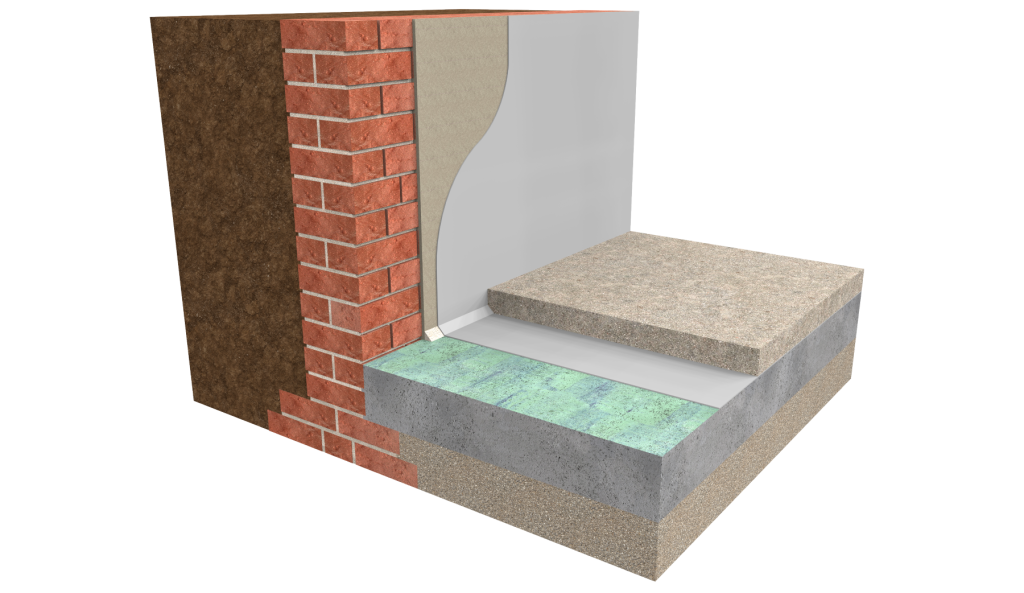

A damp proof membrane (DPM) is primarily designed to prevent moisture moving by capillary action from one building element to another. Typically installed beneath new concrete slabs, DPMs are an effective method for preventing capillary held moisture from passing to the slab. However, DPMs have no waterproofing capabilities, so they should not be used where the slab could be subjected to ground water pressure.

Key Features of DPMs

- Commonly used beneath concrete floors or screeds as a barrier to damp and to provide isolation from the floor insulation.

- Provides a barrier to isolate the slab from the damp soil.

- Often paired with a damp proof course (DPC), installed 150mm above ground level within the walls to create a continuous barrier against moisture ingress from the ground.

While DPMs are useful for managing dampness within the capillaries in the structure, their inability to resist hydrostatic pressure makes them unsuitable for basement waterproofing.

What is a Waterproofing Membrane?

A waterproofing membrane is designed to provide high quality, robust protection against water ingress for below-ground structures where hydrostatic pressure is expected. There are numerous different types of waterproofing membrane depending on how and where they are being installed, but they are essential for below-ground structures like basements, where ground water risk should be considered.

Types of Waterproofing Membranes

Different types of waterproofing membranes are tailored to specific applications:

- Cavity Drain Membranes: ‘Type C’ systems that manage water ingress by collecting and safely directing it away from the structure via drainage channels.

- Cementitious Renders or Coatings: ‘Type A’ products that are typically post-applied to the internal surface of a below-ground structure as a barrier to resist water ingress.

- Externally Applied Waterproofing Membranes: Another ‘Type A’ solution that creates a barrier to ground water, but this time around the outside of the below-ground structure. Pre-applied sheet membranes are placed onto the raft support and to construction line formwork ready for the placement of the concrete raft and walls. Where the walls are created using conventional formwork, sheet membranes or trowel-applied pastes are post-applied to the walls, lapping to the pre-applied membrane to produce a continuous, watertight envelope around the structure.

These high-quality waterproofing membranes ensure long-term protection against water ingress while complying with British Standard BS 8102:2022.

How Do DPMs Differ from Waterproofing Membranes?

| Damp Proof Membrane (DPM) | Waterproofing Membrane | |

| Purpose | Barrier to the movement of moisture by capillary. | Barrier to ground water (Type A) or as a drainage membrane diverting water to drainage channels (Type C). |

| Applications |

|

Below-ground structures such as basements. |

| Water Resistance | None. Only effective as a barrier to capillary held moisture. | Fully resistant to groundwater pressure (Type A) and as a drainage membrane (Type C) |

| Compliance with BS 8102:2022 | No waterproofing capability. | Suitable for waterproofing below-ground structures. |

While DPMs address damp issues effectively, their inability to resist any water pressure makes them unsuitable for waterproofing.

Why is a Polythene Membrane not Suitable for Waterproofing?

Polythene damp proof membranes do not have the tested performance to provide resistance to water pressure, and so cannot provide any waterproofing benefit in below-ground situations. The only exception to this is when a DPM is used inside a structure that has already been correctly waterproofed.

DPMs can provide benefits as curing membranes though, including below a basement slab or raft. They do this by preventing the blinding from pulling moisture out of the concrete, which the concrete requires for a full and correct cure. When used in this way below a slab, it is vitally important that the DPM is not turned up between the slab and wall as this creates a disconnect at this structural junction and a potentially vulnerable route for water ingress. For effective basement waterproofing, the slab should bond directly to the wall.

Can a DPM Be Used as a Waterproofing Membrane?

No, a DPM cannot replace a waterproofing membrane in below-ground applications. While DPMs prevent the passage of moisture, they lack the durability and resistance needed to withstand hydrostatic water pressure. For basement waterproofing, only products that demonstrate waterproofing performance, such as cavity drain membranes (Type C) or waterproofing barriers (Type A) should be used.

Our Waterproofing Solutions

Newton provides high-quality products designed specifically for below-ground protection:

- Type C: Cavity Drain Membranes – The Newton CDM System includes BBA-certified cavity drain membranes that manage water ingress by depressurising incoming water and safely draining it away via the BaseDrain drainage system. These systems offer reliable basement waterproofing while maintaining compliance with BS 8102:2022.

- Type A – Internally applied: Cementitious Coatings – The HydroCoat System is a range of cementitious based coatings and renders that provide negative water pressure capability, ensuring robust protection against water ingress.

- Type A – Externally applied: The HydroBond System provides external protection by forming a watertight envelope around structures.

Compliance with British Standards

British Standard BS 8102:2022 emphasises combining multiple types of waterproofing systems – Type A (barrier), Type B (integral), and Type C (drained) – for optimal protection against water ingress.

Waterproofing Design Specialists are tasked to determine the use of combined protection in various forms where, in a single system:

- the assessed risks are deemed to be high; or

- the consequences of failure to achieve the required internal environment are deemed too high

Read more on when and why combination waterproofing systems should be considered.

Choosing the Right Waterproofing Solution for Long-Term Protection

While damp proof membranes are effective at managing capillary held moisture above the ground, they cannot replace waterproofing membranes for below-ground applications such as basement waterproofing.

For robust basement waterproofing that meets British standards, construction professionals should opt for advanced solutions that combine Type A, Type B and/or Type C waterproofing systems, especially in cases where a completely dry and habitable internal environment is required.

By selecting high-quality materials tailored to specific applications and adhering to best practices, you can protect structures from water damage while ensuring long-term durability. Contact Newton Waterproofing today to explore related products and find the ideal solution for your project.

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.