01732 496 523

Radon Gas: The Hidden Threat in Your Basement

Radon is a radioactive gas formed naturally from the decay of uranium in the ground. It is colourless, odourless, and tasteless. Radon gas protection for basements is more important than ever. To protect against radon, we offer specialised, compliant solutions to protect your basement and property from this silent risk.

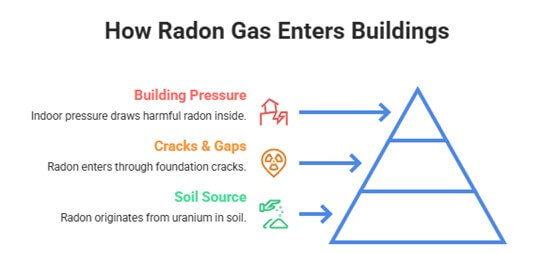

Radon enters buildings through cracks and openings in walls and floors. Due to its greater density than air, it also tends to accumulate in low-lying areas with poor airflow, such as basements.

Figure 1: A graphic demonstrating how radon gas can infiltrate properties.

Long-term exposure to elevated radon levels is the second leading cause of lung cancer in the UK, after smoking. When inhaled, radioactive particles from radon decay can damage lung tissue.

According to the Radon Council, radon causes approximately 2,000 deaths annually in the UK.

Test When Necessary: Radon testing is recommended after major structural changes, or to verify the effectiveness of a newly installed protection system.

This guide outlines key radon gas protection measures and explains when mitigation is legally required, helping builders, specifiers, architects, and environmental consultants comply with current UK radon regulations.

It focuses on the Newton PAC-500 system and how it can provide full radon measures, including the constituent parts such as cavity drain membranes, tapes, and primers required.

Since February 2023, new UK builds have been required to include radon protection under the updated NHBC Standards and Building Regulations. This is aligned with the latest mapping from the UK Health Security Agency and the British Geological Survey.

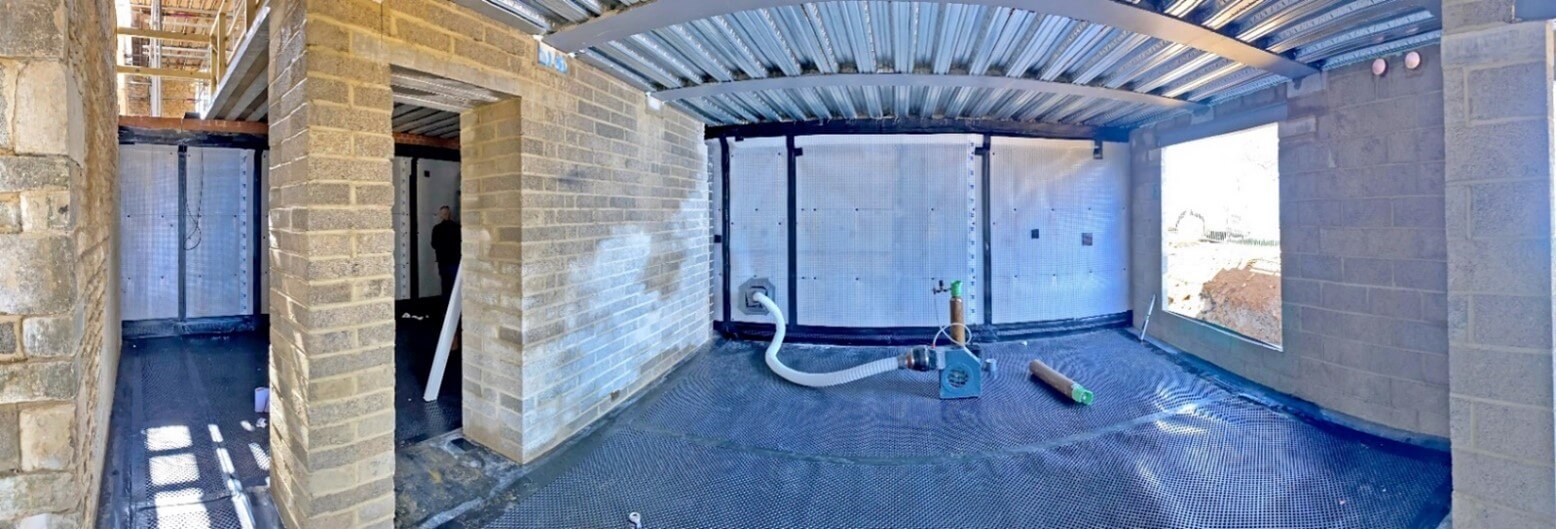

Figure 2: Radon gas protection for basements in a house using the Newton PAC-500 system.

How is Radon Different to Other Ground Gases?

Radon has specific guidance under BR211, the 6th edition of the BRE (Building Research Establishment) publication. Titled “Radon: Guidance on protective measures for new buildings.”, this document provides clear guidance on specifying and installing radon-protective measures. These solutions centre around the variations that occur regarding a building’s location and nature.

In contrast, protection from ground gases like methane and carbon dioxide is governed by BS EN 8485. This standard uses a scoring system to assess risk and determine the level of protection needed. It typically involves a combination of gas barrier membranes and ventilation. These measures are outside the scope of this radon-specific guide.

Which Safety Standards Apply?

- BR 211:2023 – Specific to radon protection in new and existing buildings.

- BS 8102:2022 – Waterproofing of below-ground structures.

How to Make a House Safe from Radon Gas: A Guide to BR211

BR211 recommends using the UK Radon Map to assess risk:

- <10% risk areas: Install a continuous radon barrier under the slab, connected to the Damp Proof Course (DPC).

- >10% risk areas: Use a radon barrier plus ventilation measures, including a radon sump.

However, BR 211 also states that all basements require at least basic radon measures to protect them, regardless of location.

Figure 3 (right): Map of areas in the UK most affected by radon gas (credit UKradon.org).

You can check your risk level by using the UK Radon Map. Despite this, BR 211 explains that because a basement property has more surfaces in contact with the ground, radon measures must be considered regardless of the geographical location. This approach acknowledges that, while radon levels can vary geographically, any below-ground space could potentially accumulate harmful concentrations of this radioactive gas.

Who is Responsible for Radon Gas Protection?

Architects, developers, and specifiers who overlook this risk not only jeopardise occupant safety. They may also be found non-compliant with best-practice regulations and liable for future mitigation costs. That’s why we recommend always specifying radon protection in basements as part of any standard approach.

Failing to incorporate radon protection from the outset can result in non-compliance and future liability, particularly for architects and specifiers. Therefore, the best practice is to install protective membranes and ventilation systems in all new basements, regardless of the location’s classification as low risk.

To create safe below-ground spaces, radon protection must be considered and integrated with waterproofing systems from the earliest stages of design. These are at the RIBA Design stages 2, 3, 4a and 4b.

What About Radon Gas Protection For Basements?

Section 6.12 of BR211 explains that basements and semi-basements are at a greater risk because their walls are in contact with both the ground and the floor.

It confirms that some certificated cavity drain membrane (CDM) systems can provide adequate radon protection when professionally installed. This includes ensuring that the wall membrane is fully sealed at the top where it connects to the ground floor or to the external wall membrane, as well as sealing connections at the head of the walls.

In areas prone to waterlogging, commonplace in many basements, the legislation also states that radon sumps may be ineffective, as subfloor depressurisation won’t reliably function. In such cases, active ventilation systems are recommended.

Quote: BR211 – ‘Radon: Guidance on protective measures for new buildings’, 2023:

“Below-ground waterproofing and radon management are specialist activities that can conflict. It is recommended that dual protection systems be designed and installed by specialists who are suitably qualified in both waterproofing and radon management.”

Combined Waterproofing & Basic Radon Protection: What Systems Do Newton Supply?

We provide systems that meet basic radon measures and comply with waterproofing regulations:

Type A – HydroBond System (Radon Certified Barrier Waterproofing):

Pre-applied membranes:

Post-applied membranes:

Type C – CDM System (Radon Certified Cavity Drain Membranes):

These systems can be combined to achieve internal environments that are not only classified as Grade 3 ‘completely dry’ spaces in compliance with BS 8102:2022 but are also protected against radon in compliance with BR 211. The goal is to create an underground space that is both safe and habitable. View more product information and documentation here.

What if Radon Gas Protection for Basements & Full Radon Measures Are Needed?

When sub-floor depressurisation (using radon sumps) isn’t feasible due to waterlogging, BR211 allows sub-floor pressurisation. This can be achieved by utilising the space behind Type C cavity drain membranes, a method which is at the core of our Positive Air Curtain (or PAC) System.

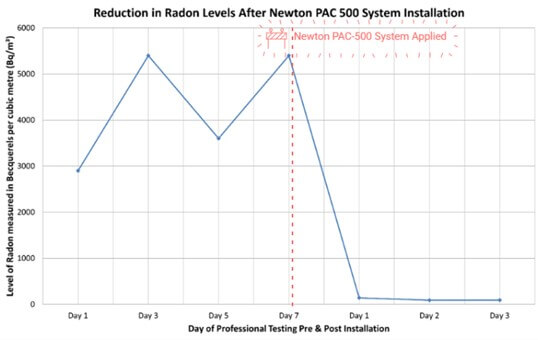

Case Study: In Derbyshire, a listed property reduced radon levels from 5,000 Bq/m³ to below 100 Bq/m³ using our PAC-500 system. Read the Case Study here.

Figure 4: PAC-500 installed in Derbyshire basement, reducing radon from over 5,000 Bq/m³ to <100 Bq/m³.

Newton PAC-500: Ideal for Full Radon Measures & Radon Gas Protection for Basements

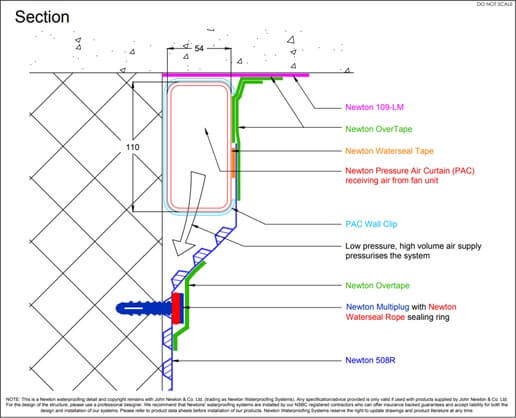

Developed in partnership with Prestige Air Ltd, the patented PAC-500 System combines waterproofing and active radon mitigation. This is achieved by combining specialist products including:

- CDM 508R Gas Barrier Membrane

- CDM BaseDrain & FloorDrain Drainage System

- Specialist fixings, tapes and ropes for creating a completely sealed system

- The Positive Air Curtain (PAC) fan system introduces air behind membranes, creating outward pressure to block radon and Volatile Organic Components (VOC’s)

Key Benefits:

- Certified protection from radon, VOCs, methane, CO₂, and water

- Integrated solution: Combines waterproofing with radon mitigation and protection in a single system

- Fully compliant with BR211, BS 8102:2022, and NHBC requirements

- The positive pressure system actively expels gases rather than drawing them inward

- Discreet and safe external venting positioned above ground level

- Installed by trained and experienced Specialist Basement Contractors (NSBCs)

- Once installed, all PAC-500 systems are independently integrity tested for airtightness with tracer gas to ensure complete system viability.

How the PAC-500 System Works

The PAC-500 System employs an 8mm HDPE cavity drain membrane installed across the floors and walls to capture incoming water and act as a barrier to radon gas. The membrane is certified for use as a barrier to radon, with the membrane joints double sealed with butyl tapes to ensure airtight integrity. The system also features a drainage channel system at key points to direct water efficiently to the Titan-Pro sump pump system.

Central to its functionality is the Positive Air Curtain (PAC). This is a low-pressure, high-volume fan system that introduces air behind the sealed membrane, creating an area of positive air pressure. This pressure barrier prevents radon from entering the property, instead pushing them out through a vent above the ground.

Figure 5: A detailed sectional diagram of how the PAC-500 System is applied and how it operates.

Radon Gas & Mitigation FAQs

What is a radon barrier?

A radon barrier is a membrane that meets the performance requirement of BR211 that stops radon gas from entering a building from the ground. It is usually installed beneath floors (for above-ground protection) and either behind basement walls or internally as a radon certified DPM from DPC to DPC or as part of a compliant internally applied combined radon and Type C waterproofing system such as the Newton CDM System (for below-ground protection).

Does every home need radon protection?

If your home is in a high-risk area or it has a basement that you want to use as a habitable space, then yes. BR211 recommends radon measures are installed in all basements.

Can I retrofit radon protection?

Yes. Newton systems can be used in both new builds and existing structures to protect against radon.

Is radon testing always necessary?

Radon testing is typically only carried out when there is a specific reason. For instance, during a new construction, after major structural changes, or when a site is identified as a higher-risk area. For existing buildings with no identified risks, routine testing is not generally required. However, if you’re unsure about your property’s radon risk, our technical team can advise on appropriate next steps.

How can I reduce radon levels in my property?

If high radon levels are identified, there are several mitigation options depending on your building’s construction stage. For new builds, radon barriers are installed above the ground slab as part of the construction process. In existing properties, internal measures such as cavity drain membranes, active ventilation systems, or sub-floor depressurisation can help reduce radon levels. Our approved contractors can advise on the best approach for your situation.

How much does radon protection cost?

Costs vary widely depending on the size, layout, and specific risk level of the property. For accurate pricing, we recommend speaking with one of our approved Newton Specialist Basement Contractors (NSBCs). They are experts in designing and installing radon protection systems to suit your site conditions, whether it’s a new build or retrofit project.

How often should I test for radon?

It’s good to test annually after a radon system has been installed or after big changes to your home. Big changes tend to include things such as building an extension or converting a basement.

Don’t Leave Basement Safety to Chance: Speak to a Radon Mitigation Expert Today

Whether you’re planning a new build or retrofitting an existing property, our technical team is ready to help. Our technical team can provide tailored support for the PAC-500 solution and other systems.

Get expert advice and design support tailored to your project’s needs.

Contact our technical team or find your nearest NSBC-certified contractor to ensure your basement or underground structure meets the latest radon compliance requirements.

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.