01732 496 523

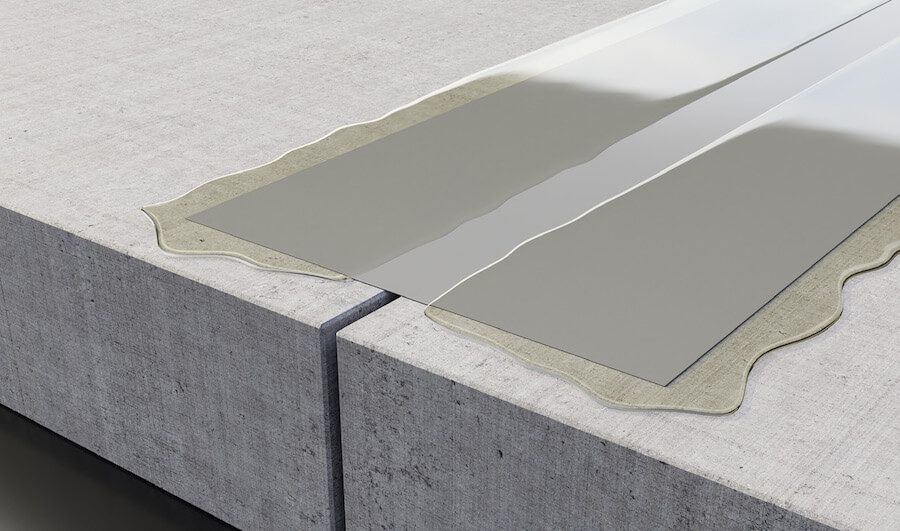

Flexible Construction Joint Waterproofing

FlexProof 106 System

External Sealing of Pipes

Hauff-Technik Sealing Systems

External Sealing of Service Entry Sleeves

Hauff-Technik Sealing Systems

Sealing of Cables & Pipes Within Service Sleeves

Hauff-Technik Sealing Systems

Concrete Tie-Bolt Hole Sealing & Waterproofing

RiveStop System

Polyurethane Injection Resins

TRADECC Injection Resins

Acrylic Injection Resins

TRADECC Injection Resins

High Performance Construction Joint Sealing

HydroCoat Monoflex

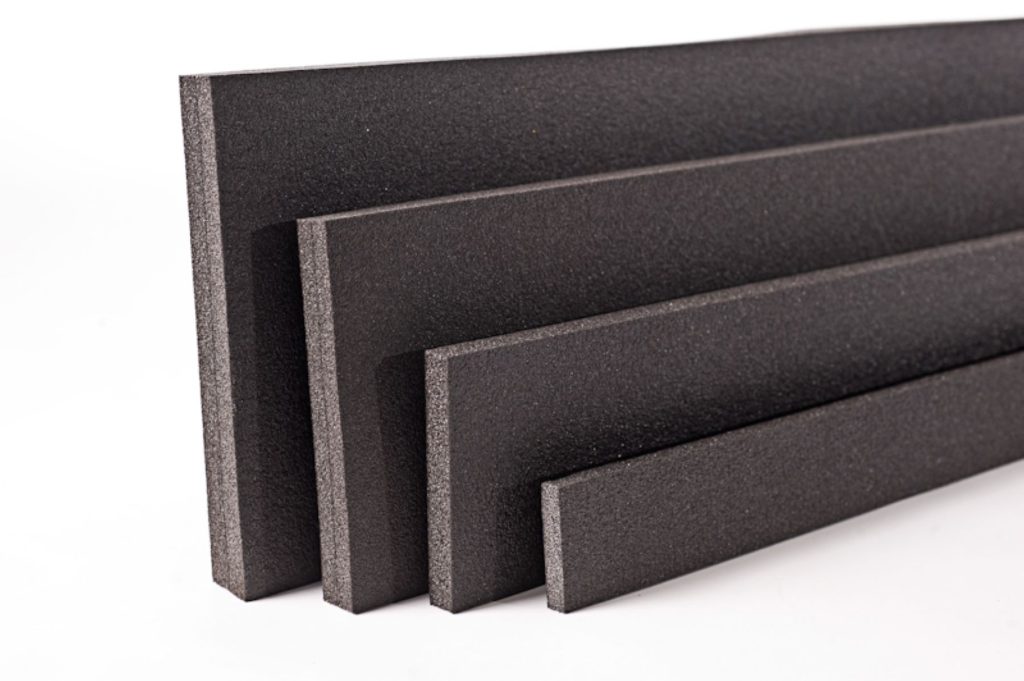

Non-Absorbent Expansion Joint Filler

Newton FlexJoint

Resin Injection Packers and Cleaning Agents

TRADECC Injection Resin Ancillaries

High Grade Hydrophilic Waterbar

HydroTank 315 Waterbar

Metal Construction Joint Waterbar

HydroTank 301-EP Metal Waterbar

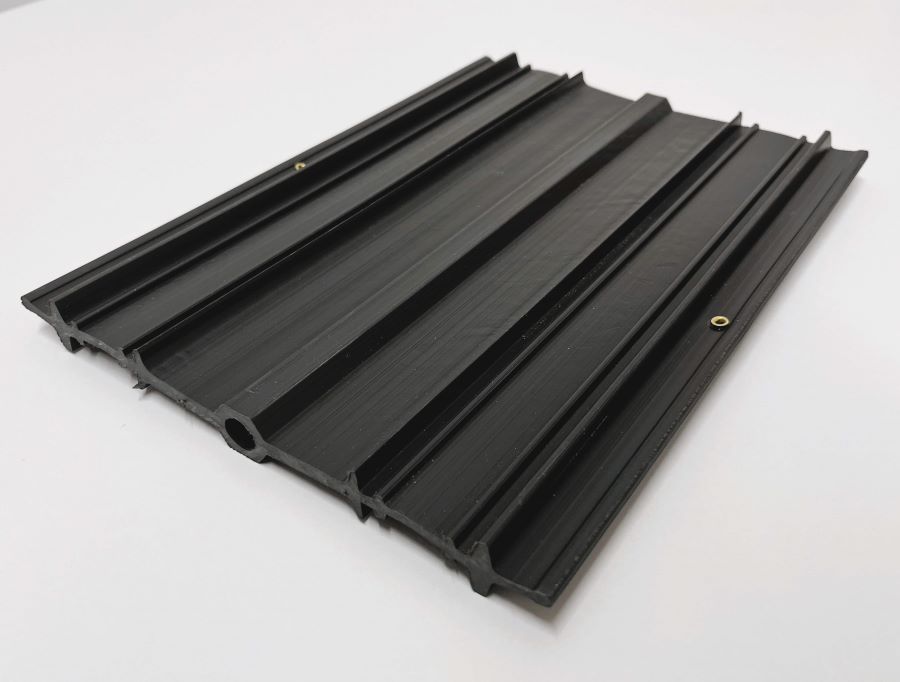

Resin Injection Hose Waterbar

HydroTank 302 Injection Hose

Movement Joint Profile

FlexProof 305 ActiveJoint - 20/26

Swelling Adhesive Mastic

HydroTank 306 Swell Mastic

Pipe Sealant Through Service Duct Sleeves

Stopaq Application Set

Elastic Adhesive Mastic

HydroTank 309 Flexible Adhesive

Fast Setting Polymer Compound to Seal Leaks

HydroCoat 313-WP

Detailing Bentonite Granules

HydroBond 314 Bentonite Granules

PVC Construction Joint Waterbar

HydroTank PVC WaterStop

Single-Use Kit for Sealing Structural Leaks

Leakplug

Concrete Joint and Leak Sealing

A range of products used to waterproof construction joints and movement joints of retained concrete structures so that they become integrally waterproof.

The Importance of Concrete Joint Sealing

Concrete joints are essential. They allow the concrete to shrink as it dries, preventing internal restraint which would lead to cracking, and they also allow it to expand and contract under different temperature conditions.

Whilst there are different types of concrete joints, if the structure is below ground then it needs to be protected against water ingress, and waterproofing products will be required to seal them. This is as well as any service or pipe penetrations and any cracks that may also appear in the concrete.

Concrete joint sealing products allow the structure to expand, contract and move without affecting its waterproofing integrity and even prevent contaminants in the soil from entering the structure.

Newton’s Concrete Joint and Leak Sealing Products

Our innovative range of products can be used to waterproof joints in concrete and provide a Type B waterproofing structure that acts as the primary form of resistance to water ingress. This includes all below-ground structures, including tunnels, basements, water tanks, and podium decks.

Concrete injection resins are also an effective method of leak sealing in a wide range of scenarios. From creating Type B waterproof structures using injection hoses to repairing leaks and cracks in existing concrete structures.

Have a read of these projects where concrete joint and leak sealing were successfully addressed.

- Waterproofing the Limehouse Link Tunnel, London

- Injection Hose Waterproofing, Jersey

- Resin Injection Leak Sealing, London

Newton 302 Injection Hose

Newton 302 Injection Hose is a high-performance waterbar system for sealing construction joints in earth retaining and water retaining concrete structures. The waterbar is installed within the joint and, once the concrete is cured, an injection resin is pumped into the hose under pressure. The resin penetrates the surrounding concrete within the construction joint, and cures to create a permanent seal for any cracks, capillaries, pores, and honeycombing within the structure.

Depending on the injection requirement, Newton can supply the whole range of high quality acrylic and polyurethane resins from our specialist resin supplier Tradecc.

FAQs

How do you permanently waterproof concrete?

There are several methods to permanently waterproof concrete, including the use of concrete sealers, membranes, and coatings. Concrete sealers are liquid coatings applied to the surface of the concrete to form a water-resistant barrier. Membranes are sheets of waterproof material laid over the surface of the concrete before it is poured. Coatings are applied to the surface of the concrete after it has been formed and are thicker than sealers.

Is a concrete waterproofer the same as a sealer?

Sealers and waterproofers perform similar functions, but they differ slightly in how they work. A wood or concrete sealer will protect the surface. Waterproofers are more durable than sealants because they penetrate the surface, filling in leaks or gaps.

Click on the boxes below to find out more about Newton’s concrete joint and leak sealing products

- Flexible Construction Joint Waterproofing

- Resin Injection Packers and Cleaning Agents

- External Sealing of Pipes

- External Sealing of Service Entry Sleeves

- Sealing of Cables & Pipes Within Service Sleeves

- Concrete Tie-Bolt Hole Sealing & Waterproofing

- Polyurethane Injection Resins

- Acrylic Injection Resins

- High Performance Construction Joint Sealing

- Non-Absorbent Expansion Joint Filler

- High Grade Hydrophilic Waterbar

- Detailing Bentonite Granules

- Structural Sealing Systems

- Metal Construction Joint Waterbar

- Resin Injection Hose Waterbar

- Movement Joint Profile

- Swelling Adhesive Mastic

- Pipe Collar To Provide Physical Waterbar

- Pipe Sealant Through Service Duct Sleeves

- Elastic Adhesive Mastic

- Fast Setting Polymer Compound to Seal Leaks

- PVC Construction Joint Waterbar

- Single-Use Kit for Sealing Structural Leaks

When Are Acrylic Injection Resins Needed? Acrylic injection resins are a valuable tool for addressing deterioration of concrete and preventing structural damage. They are primarily used for sealing leaks and cracks in concrete structures, offering a highly effective solution in various situations: Waterproofing cracks and joints: This is their most common application, addressing leaks in walls, floors, basements, underground structures, and other concrete elements, ultimately contributing to the protection of concrete from further water damage. Curtain injection: This technique creates a waterproof barrier on the external applications of a building by injecting the resin into the ground around the foundation, effectively preventing water ingress from the exterior. Membrane injections: These injections are used to create a watertight barrier behind existing structures, such as retaining walls, providing crucial protection of concrete from water infiltration on the inside. They are particularly well-suited for these applications due to their several key properties: Low viscosity: This allows them to penetrate even the finest cracks, ensuring a thorough and complete seal. Hydrophilic: They absorb water, causing them to swell and further tighten the seal, ultimately leading to a more effective repair. Elasticity: This allows them to accommodate movement in the structure without cracking, providing a long-lasting solution. Therefore, whenever you encounter leaks or cracks in concrete structures that threaten the integrity of the building or require protection of concrete from further deterioration, acrylic injection resins can be a highly effective repair method to consider. However, it's important to consult with a qualified professional to determine the most appropriate and effective repair solution for your specific situation.

Speak to our friendly, expert team

Our staff are able to provide guidance for projects of all sizes, whether you require some general advice about damp or waterproofing, or support with technical drawings and specifications.